Revolutionizing Additive Manufacturing: Towards a Circular Economy

Smart Materials for Sustainable Additive Manufacturing

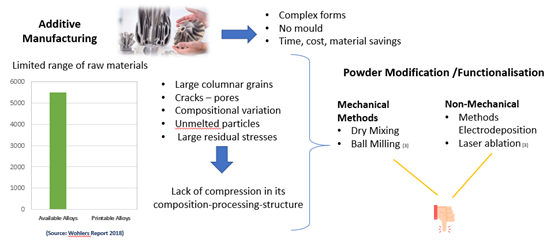

Additive Manufacturing (AM) has the potential to transform the circular economy through innovative material options, customized designs, and more sustainable processes. It also enables higher-quality products and simplifies resource recycling.

Current Limitations: Inefficiency and Limited Material Availability

Despite its promise, AM faces challenges such as inefficient processes and a limited range of materials. Only a few metals, such as AlSi10Mg, TiAl6V4, and Inconel 718, can be reliably produced, while metal-ceramic composites encounter difficulties due to thermal incompatibility and phase segregation.

Innovation with Smart Hybrid Powders (SHP)

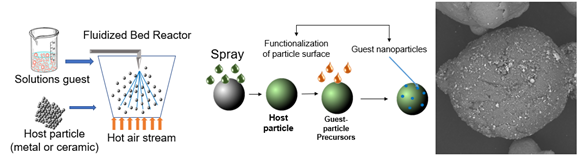

The project proposes a revolutionary solution: the design, production, and evaluation of Smart Hybrid Powders (SHP) with tailored characteristics for AM. These powders will be functionalized in a fluidized bed reactor, controlling their microstructure to manufacture defect-free, high-quality components.

Two Approaches for Advanced Materials

- Nanoparticle-coated powders: Control solidification and grain growth, improving the microstructure.

- Metal-coated ceramic particles: Ideal for metal-ceramic composite materials.

Benefits: Towards Sustainable AM

Using tailor-made powders and controlled process parameters will deliver more durable components, fewer defects, reduced raw material usage, and waste reduction, promoting sustainability in AM.

A Groundbreaking and Revolutionary Technology

The project combines alloy design, innovative processes, and multiscale modeling to open new possibilities for more efficient and sustainable AM. This unprecedented approach promises to redefine the future of advanced manufacturing.